Just in any product centric industry, ‘Quality’ is the backbone of success when it comes to textile and apparel industry.

Today brands and retailers walk on a tightrope when it comes managing quality from inline inspections to final checks. Defects can happen randomly and if not identified on time can disrupt workflow and cause extra usage of resources, effort, and time on rework.

For most brands, the cost of poor quality can be as high as 25% of sales and if the reasons are unknown then it can even exceed the profit margin. The brand’s revenue, retaining existing customers, and adding new ones all hinges on delivering ‘good quality.’

However, given the scope and intricacies in developing a textile product, ensuring quality is easier said than done. A textile brand has to manage things on multiple fronts be it the complexities of global supply chains, stricter compliance regulations, and heightened customer expectations.

Brands must adopt robust quality management solutions to effectively navigate the challenges and ensure the quality and integrity of their products.

The Common Challenges in Textile Quality Management

%20(1).jpg)

Textile production involves multiple processes from sourcing of materials to cutting, sewing, washing, finishing, and shipping. Minor or major issues can develop anywhere along the production lines which is why textile quality inspection is required on every stage.

Here are the most common problems and challenges

- Traditional methods rely on paper-based methods that require filing, organizing, and debriefing meetings that leads to delayed responses and unfixed problems.

- Managing diverse production lines is a big operational challenge. Each line consists of different materials, processes, and potential points of variation.

- Variations in fabric is another major challenge that causes inconsistencies in texture, strength, and dye absorption.

- Most apparel brands work with hundreds of manufacturers, suppliers, and retailers across the globe. Communication barriers and differences in production standards make it difficult to ensure consistent product quality.

- Failure to meet quality standards and production requirements within the timelines results in significant problems. This includes order cancellations, financial penalties, and the urgent need for proactive quality control.

What is QUONDA?

It is a textile quality management solution that allows brands, retailers, and manufacturers to digitize, analyze and prioritize their key supply chain processes. QUONDA is a holistic inspection control solutions textile that provides digital features to perform quality control tasks.

It is an established digital software developed by Triple Tree Solution that has been in the textile industry for over 25 years. The company is determined to improve the textile and apparel processes through fully customizable, cloud-based solutions.

Triple Tree offers QUONDA, ColordesQ, and TrackIT to navigate the complexities of sourcing, quality control, color management, production, and distribution.

QUONDA is in use by over 3,400 users in 45 countries to perform more than 50,000 inspections per month.

How does it benefit textile and apparel brands?

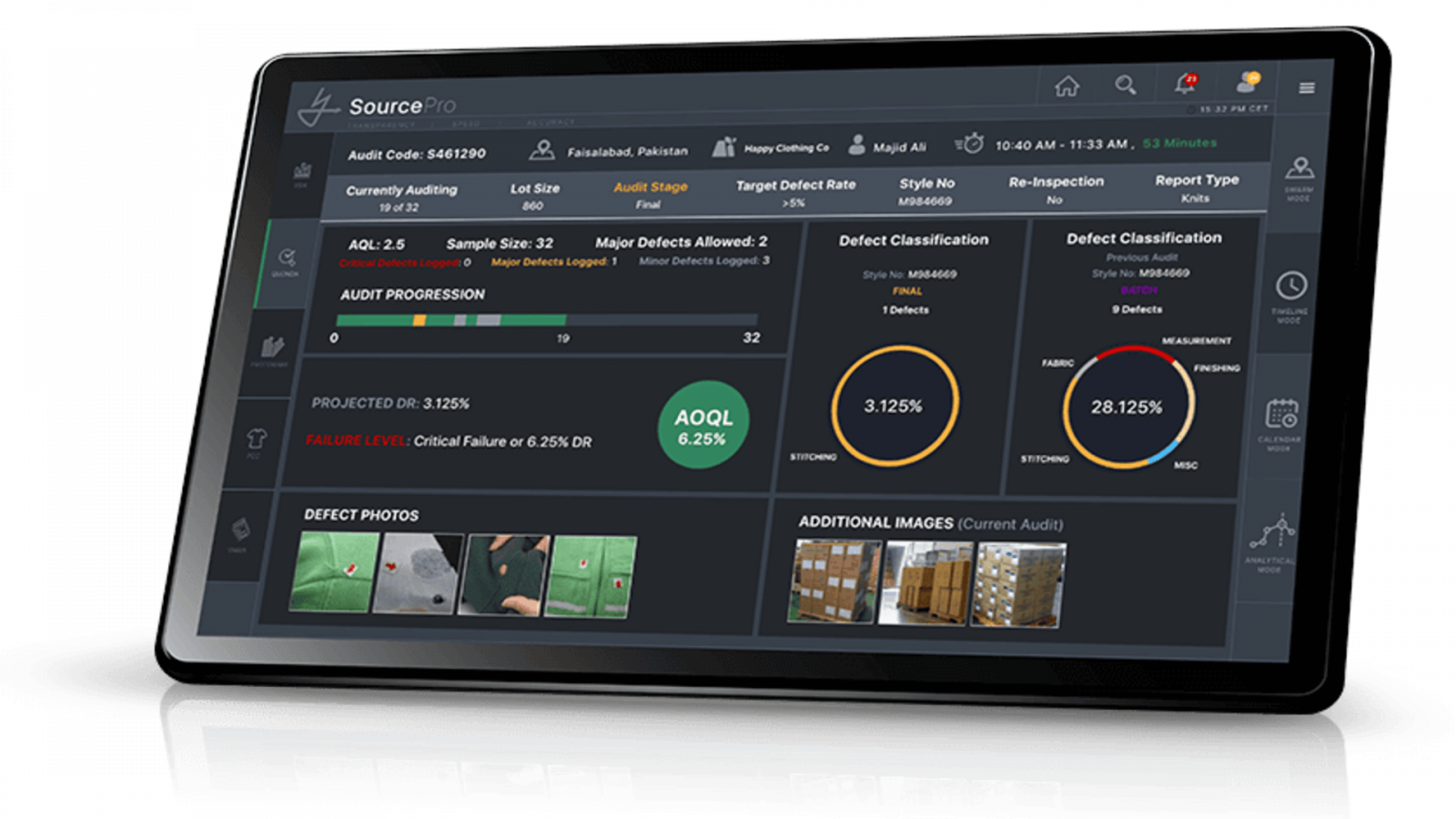

Holistic Platform: A user-friendly dashboard not only with clear visibility but advanced tools to schedule, manage, and review crucial textile supply chain quality management processes.

Customization: It recognizes diverse operational landscapes and that each client has unique needs. QUONDA offers a tailored and flexible approach to fit specific requirements involving inline quality inspection and final product inspection.

AI-Powered SaaS: As a fully customizable AI-based SaaS solution, it provides seamless adaptation to existing textile-specific processes and workflows.

Real-Time Data: Utilizing real-time data collection, reporting, and analysis, QUONDA streamlines both pre-production inspection and final checks. This provides immediate and actionable insights into product quality at critical points in the production cycle.

Bluetooth e-Tape Integration: It simplifies and accelerates the measurement-taking process considerably compared to traditional manual methods. This tool enhances efficiency and accuracy during inspections.

Comprehensive Summary: Upon completing inspections, the production team can access the dashboard for a clear and concise summary. They get access to real-time reports, can check the quality status and make informed decisions.

Textile Quality Management: Manual Methods vs. QUONDA

Traditionally, textile quality checks were done using manual methods. A team of inspectors physically examine the textile through each of the processes from fabric selection, cutting, dyeing, and finishing. This subjective evaluation is still practiced but quality inspection software is being used increasingly due to its speed, accuracy, and consistency.

Here is how the two stack up in comparison

Traditional Quality Inspection Process

| Digital Quality Inspection Process

|

|

|

|

|

|

|

|

|

|

|

READ: How QUONDA a better solution than Manual Inspections

QUONDA Features

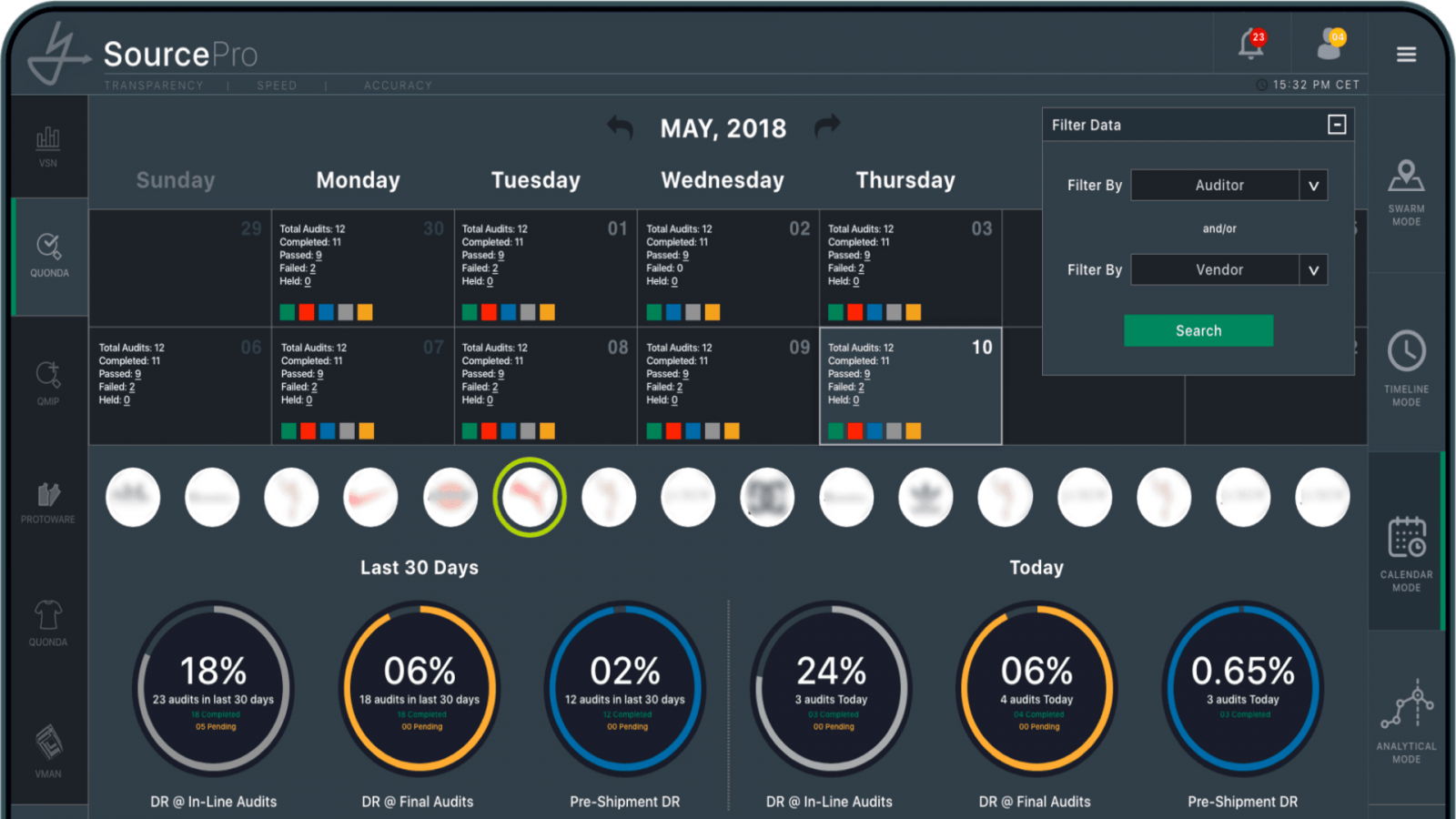

Audit Scheduling: Efficiently schedule, conduct, and manage inspections through a centralized dashboard.

Inspection Team Management: Track inspection progress and assess overall performance through a timeline-based dashboard.

Live Inspection View: Get visibility into ongoing inspections. Detect non-compliance promptly during inspections and with established sampling protocols.

Measurement Efficiency: Reduce inspection time by one-third with e-Tape app integration. It automates all the measurement taking tasks.

Bird’s Eye View: Track live inspection activities across entire production line globally via a map-based dashboard interface.

Customizable Reports: Generate tailor-made report formats of different brands and operational divisions within your organization.

Dashboards & Analytics: Leverage quality data to access detailed summaries and measurement breakdowns for informed decisions.

Want to Upgrade Your Textile Operations – Explore the Features of QUONDA Now

How QUONDA Works

.png)

QUONDA is a digital quality management (solutions) apparel and works like most other productivity software. However, as it allows to check quality for different processes, let us divide this it in sections.

1. Login

- Enter the username and password given by Triple Tree. The authorized person can even use a fingerprint if using mobile version of the software

- Once logged in, you get two tabs ‘To Do Inspections’ and ‘Completed Inspections’

- The To Do Inspections consists of Inspection Stage, Vendor Information, and Order Size

2. Scheduling an Inspection

- Click on ‘Select the Report’

- Select the Report type from the list and it will take you to previous screen where you have to press ‘Next’

- Click on the Inspection Stage

- QUONDA will show you the relevant stage against the report type that is selected

- Select the Brand and Vendor

- Once you enter first two digits of the PO number, the software will automatically retrieve the matching PO numbers based on brand and vendor

- Choose the required PO from the list

- Choose the required color, style, and size.

- Select the inspector and date/time for the inspection. By default, the inspector will be set for your user profile.

- After ensuring you have filled the necessary details, tap ‘Schedule’

3. Inspection Process

- Click the ‘Play’ icon to start the inspection and proceed to the next steps.

- Note, you can edit the inspection by clicking the Edit icon, but once the inspection starts, the edit option will no longer be available.

- Ensure all requirements are filled and then click ‘Start’

- Tap on ‘Description/Quantity of Product’ to create lots for the inspection

- Click on ‘Plus’ button to add a Lot

- Select the Style, PO, Color, and Size and Enter Lot Size. Then tap on ‘Save’ to add the Lot.

- You can add multiple lots in the same manner. After adding them, the software will show you the sample size. Then click on ‘Save’

- Tap on ‘Workmanship’ when you begin to inspect the garments to record your findings

- QUONDA will display AQL level, allowed defects, and other information. To begin this process, tap anywhere on the Lot number. If there are multiple lots, then you have to complete each section individually.

- For each textile product or garment, you have to do a physical inspection and record the results here.

- You can either approve the garment if there are no defects or classify the defects as minor, major, or critical.

- Color codes are as given, Green for ‘Approved’, Yellow for ‘Minor’, Orange for ‘Major’, and Red for ‘Critical’

- Click on ‘Plus’ Button to add picture of the defect and add image from gallery section of the mobile phone.

- Select the defect type, code, and position and then click on ‘Submit Defect’

- After adding the defect, the ‘Approved’ button will change to ‘Next.’ If there are other defects in the same sample, then you will have to add each defect separately.

- Once you finish a lot, the software will automatically highlight it with a green border, which indicates that this lot inspection is completed

- Click on the graph button to view the ‘Analytics’ of the added defects

- You can see the number of samples for each defect type. To view the details of each defect, click on ‘Arrow Button’.

- You can edit or delete the defect if it was added mistakenly

- After completing the section, the system will display a green line if the result was ‘Pass’ and a red line if it was ‘Failed’

- Click on ‘Message Conformity’ to add the measurement specifications.

- Tap on the ‘Attach Spec Sheet’ button

- Add the Image and Caption and then save it

- You can add or delete multiple images. Once all are added, go back and select the ‘Measurement result’ and save it.

- Click on Sales/Packaging/Labeling

- Enter the total cartons available and cartons picked for inspection

- You can enter the carton number manually or scan the barcode.

- Tap on ‘Defective’ if you have to add a defect

- It is mandatory to add image for the defect in this section

- After adding the image, enter the defect code and save it.

- If there are multiple defects on the same sample, then select ‘Add defects’ to include the additional defects

- Otherwise, tap on ‘Next’ to move to the next step

- The results will automatically be populated and click on ‘Save’

- The Labeling section is same as the Packing section

- You can add pictures by selecting the ‘Add Packing/Labeling Pictures’ button

- Add the image and caption and then save it

- If you add a Major or Critical defect in the Workmanship section, the CAP will appear. You have to add the cause of the defect and other relevant information

- To begin this section, tap on ‘CAP’

- Select the root cause, corrective action, and any other required fields.

- After confirming the information, save it

- Click on ‘Checklist’

- Select the required percentage by dragging the scrollbar

- For the text fields, enter the relevant information

- For fields other than text, select ‘Yes’ or ‘No’ or ‘N/A’

- The fields relate to the Measurement test that are done manually. Enter those values.

- After completing all the Checklist items, click on ‘Submit Results’ to save the data.

- The system will generate the ‘Inspection Result’ based on all the previously completed sections.

- You can add any additional documents by tapping on the ‘Attachments’ button

- Only files of the allowed type can be added. For example, PDFs to the PDF box, Word documents to the Word box, and Excel sheets to the Excel box.

- You can also add additional images, give it a caption, and save it

- Tap on ‘Signatures’ on add your signature

- Draw the signature and save it

- Add any comments related to the inspection and select ‘Finalize the Inspection’

- The system will generate a ‘Pop-up’ for confirmation.

- Select ‘Yes’ to finalize the inspection or ‘No’ to keep working on it

4. Syncing Process and Report Viewing

- After finalizing, all the buttons on the dashboard will disappear as the inspection is concluded and is being uploaded in the system

- To view the ‘Syncing’, click on the main menu and select the ‘Sync Status’

- The time taken for the syncing will depend on the speed of the internet and also on the quantity and sizes of the documents and images.

- When the inspection is synced successfully, it will be moved to the ‘Completed Inspection section.’

- Tap on the ‘Completed Inspection’ to view the results

- You can even click and open the ‘Digital Report.’ View all the inspection data and there is also the option to send the report to another user

- Enter the email address of the recipient and tap send

- You can also download the PDF version of the Inspection Report by clicking on the PDF button

Case Study: How QUONDA helped a Sourcing Giant Transform its Operations

QUONDA Advantages

Real-Time Activity Status: Gain immediate insights into real-time activity of all quality related processes across the production line.

Live Dashboards: Utilize the live and interactive dashboards to get updates of critical quality metrics and other emerging productivity trends.

IoT Integrations: Integrate with IoT devices for enhanced measurement accuracy and efficiency. An example is the e-tape for automated and accurate data collection.

Easy Access: Easy and secure access of the platform and analyze inspection from any location and from any time via web and mobile applications.

Informed Decisions: QUONDA is both an initial and final inspection quality control solution that empowers stakeholders with real-time data to make clear and informed decisions regarding quality control.

Meet Global Standards: Digitizing the inspection process streamlines the production processes, reduces the risk of defects, and ensures consistent quality.

Error Reduction: Eliminate errors, increase productivity, and reduce costs through streamlined processes.

Input Inspection Data: Easily input inspection data during the process which eliminates the need for manual data entry and ensures accurate records.

Cost-Effective Pricing: Benefit from competitive pricing that provides significant value and strong return on investment.

Clear ROI Metrics: Data-driven insights to effectively address any concerns regarding the initial investment and the adoption process.

Sustainability Support: QUONDA provides data visibility and helps assist in complying with international sustainability initiatives like CSDDD and promote eco-friendly practices.

QUONDA: Pros and Cons

Pros:

- Digital inspections that save considerable time, effort, and resources

- Tailored solutions to fit specific client needs.

- Streamlined processes leading to time and cost savings.

- Seamless integration with existing systems and IoT devices.

- Intuitive interface ensuring ease of use.

Cons

- Initial setup may require time for customization and training.

- Cloud-based nature necessitates reliable internet connectivity.

QUONDA: Frequently Asked Questions (FAQs)

Q: What types of inspections does QUONDA support?

A: QUONDA supports both inline inspections during the production process and final inspections of finished goods, providing comprehensive quality oversight.

Q: Is QUONDA a customizable solution?

A: Yes, QUONDA is a fully customizable AI-based SaaS solution designed to adapt to your specific textile processes and workflows.

Q. Is QUONDA easy to integrate with existing systems?

A. Yes, QUONDA is a versatile textile quality inspections software offering smooth integration with existing inspection processes, ERP systems, and IoT devices to enhance workflow without requiring complete overhauls.

Q: Can I access quality data in real-time?

A: Yes, QUONDA offers real-time data collection, reporting, and live dashboards, providing immediate insights into your quality metrics.

Q: Does QUONDA help with sustainability initiatives?

A: Yes, QUONDA provides data visibility that can help your organization align with and support international sustainability initiatives.

Q. Does QUONDA offer mobile functionality for inspectors in the field?

A. Yes, QUONDA is fully mobile-enabled, allowing inspectors to perform inspections, upload data, and generate reports on-site using smartphones or tablets.

Q. How does QUONDA improve inspection accuracy?

A. With real-time data entry, automated measurements, and smart alerts, QUONDA reduces manual errors and ensures every quality checkpoint is tracked and verified.

Q. Can QUONDA handle multiple factory locations globally?

A. Absolutely, the textile quality management solution supports multi-location operations and provides a centralized dashboard to monitor inspection activities across all global manufacturing sites.

Q. How does QUONDA help with decision-making?

A. QUONDA offers live dashboards and analytics, giving stakeholders instant access to quality metrics, enabling faster, more informed, and proactive decision-making.

Optimize Your Textile Supply Chain Processes and Ensure Superior Quality